Help Isom IGA recover from devasting floods

4 min read

Electronic Shelf Labels Deliver Flexibility & Eliminate Pricing Errors

Written by Jessica Vician

Jul 19, 2023

Electronic shelf labels (ESLs) are an investment, but the flexibility for quick price changes and reduction in labor required have made them an attractive option for independent grocers.

“With labor shortages and inflationary times, now is the appropriate and right time to do it,” Maurer's Market Owner Jeff Maurer says of his decision to switch to electronic shelf labels.

Traditional shelf labels may seem simple and easy, but when considering the challenges, ESLs become increasingly more attractive, Maurer says. Challenges to traditional shelf labels include:

- Reduced staff productivity: considerable time and labor required to change and maintain printed shelf labels

- Pricing integrity issues: ensuring pricing consistency between shelf price and POS price

- Pricing flexibility issues: pricing agility, like happy hour and market-driven pricing

- Stock concerns: out of stock on the shelf or missing/lost labels

Maurer's Market uses three designs on their ESLs: black and white is regular pricing; small red box (as seen above) denotes a temporary price reduction; all red signifies a product in the weekly circular.

What are the benefits to ESLs?

A digital alternative to traditional paper shelf tags, electronic shelf labels display the same information — product name, price, and reorder number — but the technology eliminates the challenges of paper shelf tags. Electronic shelf labels key benefits include:

1. Real-time pricing & updates

"Our costs are changing constantly, so we are now in a position where we can make those retail price changes much more quickly, much more efficiently than we ever could before," Maurer says.

"We're getting thousands of price changes every week. Before, that was a manual process," Maurer adds, detailing the need to print, separate, and hang shelf tags. "It was extremely time consuming and prone to error.

We did 1,400 price changes on Monday in less than 10 minutes. Before that it would have taken four days."

2. Reduced labor cost

In fact, the process is so efficient, Maurer says his employee can do the pricing from home. His licensed distribution center (LDC) sends the pricing batches on Monday morning and the updates are done before the employee leaves home for the store.

That flexibility also helps reduce the store's shrink. "If we're heavy on a product and have excess inventory, we could make a decision at that moment to reduce the price to try to help move that inventory along faster," Maurer explains.

3. Accuracy and consistency

The electronic shelf labels make it easy to ensure shelf pricing is the same at the POS, thanks to integration with cloud platforms. A pricing update is sent to the labels and cash registers at the same time, significantly reducing the risk of error.

That frees up employees' time to focus on customer service and other value-adds. Employees spend 80% less time on paper tag updates on average once a store switches to ESL, according to SES Imagotag, the ESL provider Maurer uses.

4. Centralized control and analytics

The platform's centralized information for products allows for seamless standardization, whether the ESLs are used in a single store or a large store group. That means inventory management, price adjustments, sales analytics, and more can be easily accessed, analyzed, and managed for more efficiency and consistency across departments and stores.

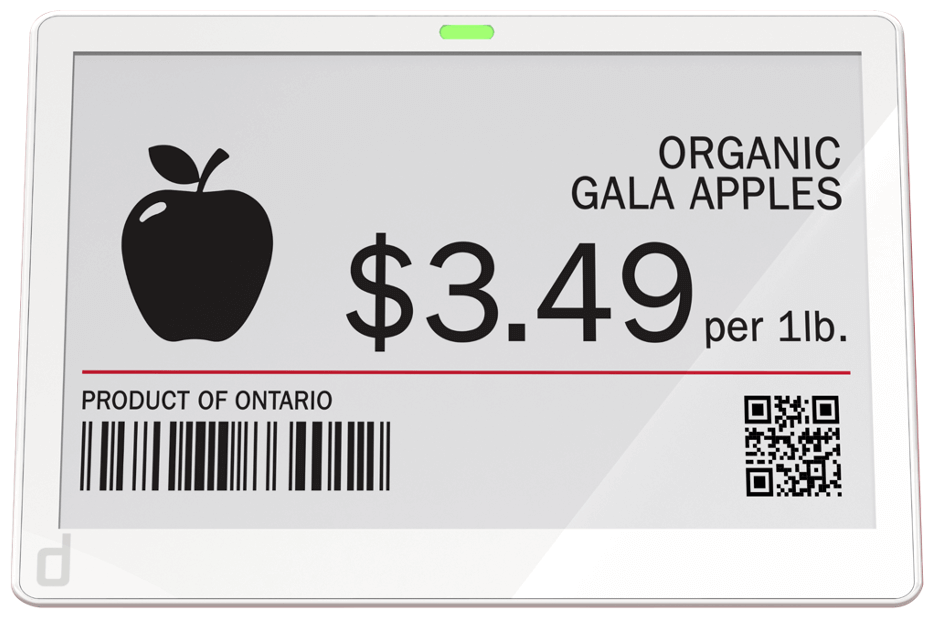

A Danavation digital smart label

A Danavation digital smart label

What is the cost and ROI?

Each electronic shelf label provider will have their own pricing model, but in general the investment is about $11-12 per label. That price includes:

- Hardware (variable labels)

- Software

- Clips

- Rails (so the labels stay in place)

For Maurer, who has about 20,000 SKUs in his store, the investment ran about $208,000. He says he was afraid of the cost at first, but after his pricing person retired, he opted to move forward with the labels instead of hiring a replacement employee, and doesn't regret it.

"Don't wait any longer. I wish I would have done it a couple years ago," Maurer says. "It's a costly decision to make, but I know it's going to have a very very quick return on investment."

Maurer predicts the return on investment will come in 1.5 to 2.5 years, with 50% of that coming from reduced labor and paper supplies, including: spending less on printing, eliminating labor on sorting and hanging the labels, implementing dynamic pricing based on inventory levels.

The dynamic pricing will also drive higher margins by allowing the team to make better daily pricing decisions based on product availability, making up about 16% of the ROI.

Shannon Clark, director of brand and marketing at Houchens Food Group, piloted two stores with ESLs and is planning to launch two more stores in the near future. Her calculated ROI is 3.5 years based on paper tag, labor, and the ESL costs.

“We are pleased with our pilot and hope to expand it in the future,” Clark says.

Both Clark and Maurer praise the roll out time, with Maurer's taking about four days in January 2023 and Clark noting that the roll out speeds up as they add more stores, with the most recent up and running in 1.5 days.

Jeff Maurer shares his experience with electronic shelf labels in this video.

Who to contact?

Ready to get quotes on electronic shelf labels for your store? There are many suppliers offering electronic shelf labels today. Check to see if your LDC has a program, or contact the Independent Grocers Alliance for information on group discounts.

Previous Story

← Camano Plaza IGA Runs For Local Cause & Wellness

You May Also Like

These Stories on Feature Story

Feb 5, 2026 6:52:32 PM |

2 min read

No Comments Yet

Let us know what you think